Products

Home | Products

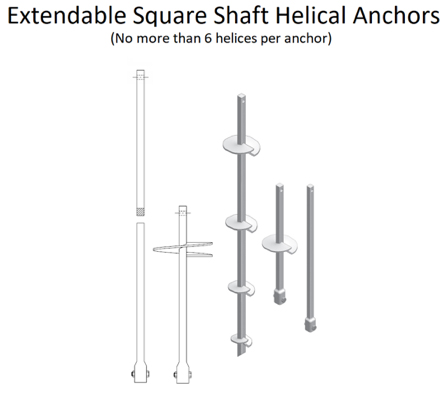

Extendable square shaft helical anchors

The range of extendable square shaft helical piles / anchors to be used by AHPAC will be used to resist axial compression, axial tension, and/or lateral loads from a variety of structures. It consists of a central steel shaft with one or more helical-shaped bearing plates welded to the central shaft. The central steel shaft can be a one-piece (non-extendable) or fully extendable with one or more extension shafts, couplings, and a bracket / termination that allows for connection to building structures. The helical pile / anchor is screwed into the ground by application of torsion and can be extended until a required depth or a suitable bearing soil stratum is reached. Load is transferred to the soil through the helix bearing plates.

The square shaft helical anchors are available in 32mm to 57mm square sizes.

Helical pile / anchors sections are joined with bolted couplings. Installation depth is limited only by soil density and practicality based on economics. A helical bearing plate or “helix” is one pitch of a screw thread.

Most helical piles include more than one helix plate, and the plates are arranged in a “tapered” configuration with the smallest helix being in the bottom and the largest helix being on the top. The large majority of helix plates, regardless of their diameter, have a standard 76mm pitch. Being a true helical shape, the helix plates do not auger into the soil but rather screw into it with minimal soil disturbance.

Helix plates are spaced at distances far enough apart that they function independently as individual bearing elements; consequently, the capacity of a particular helix on a helical pile / anchor is not influenced by the helix above or below it.

The starter section or “lead” section contains the helix plates. This lead section can consist of a single helix or up to four helices. Additional helix plates can be added, if required with the use of helical extensions.

Standard helix sizes and areas are shown in the table below. The full plate projected area includes the area occupied by the central steel shaft.

Most of the helical plates are provided with a sharp leading edge, which is the frond edge of the helix that penetrates the soils as the helical anchor / pile is advanced clockwise through soil. The sharp leading edge enables the helix to better slice through soils and roots.

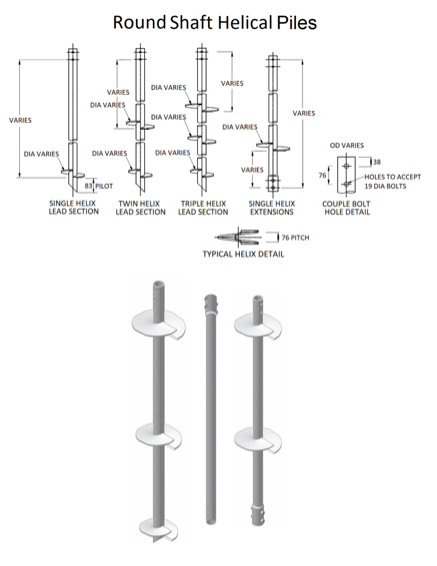

Extendable round shaft helical piles

The range of extendable round shaft helical piles to be used by AHPAC will be used to resist axial compression, and/or lateral loads from a variety of structures. It consists of a central steel shaft with one or more helical-shaped bearing plates welded to the central shaft. The central steel shaft can be a one-piece (non-extendable) or fully extendable with one or more extension shafts, couplings, and a bracket / termination that allows for connection to building structures. The helical pile is screwed into the ground by application of torsion and can be extended until a required depth or a suitable bearing soil stratum is reached. Load is transferred to the soil through the helix bearing plates.

The round shaft helical anchors are available in 73mm to 114mm outside diameter shaft sizes.

Helical pile / anchors sections are joined with bolted couplings. Installation depth is limited only by soil density and practicality based on economics. A helical bearing plate or “helix” is one pitch of a screw thread.

Most helical piles include more than one helix plate, and the plates are arranged in a “tapered” configuration with the smallest helix being in the bottom and the largest helix being on the top. The large majority of helix plates, regardless of their diameter, have a standard 76mm pitch. Being a true helical shape, the helix plates do not auger into the soil but rather screw into it with minimal soil disturbance.

Helix plates are spaced at distances far enough apart that they function independently as individual bearing elements; consequently, the capacity of a particular helix on a helical pile / anchor is not influenced by the helix above or below it.

The starter section or “lead” section contains the helix plates. This lead section can consist of a single helix or up to four helices. Additional helix plates can be added, if required with the use of helical extensions.

Standard helix sizes and areas are shown in the table below. The full plate projected area includes the area occupied by the central steel shaft.

Most of the helical plates are provided with a sharp leading edge, which is the frond edge of the helix that penetrates the soils as the helical anchor / pile is advanced clockwise through soil. The sharp leading edge enables the helix to better slice through soils and roots.

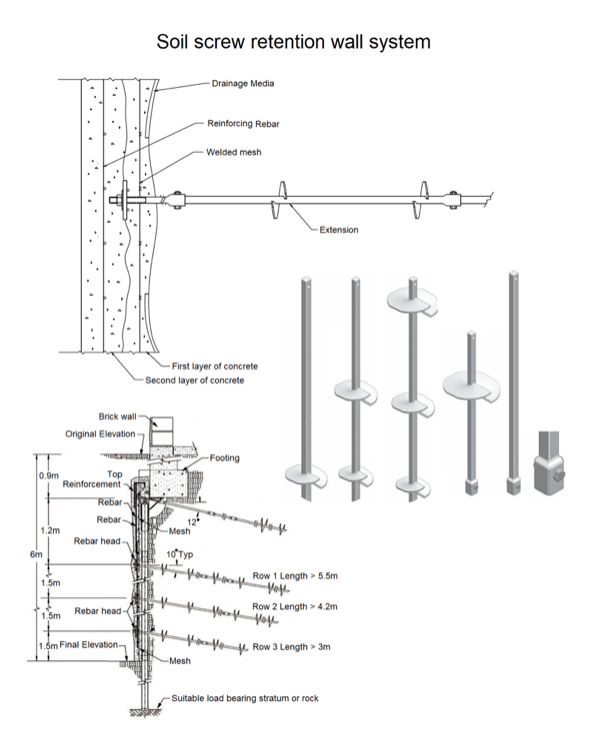

Soil screw retention wall system

The soil screw retention wall system is an efficient and economic system to retain soil during excavation and construction of structures below grade. The following are some of the advantages of this system over other soil retention methods:

– Fast installation without specialized equipment;

– Immediate support without curing time;

– Reduced installation time –post-tensioning not required;

– No need for heavy reinforced walls;

– Immediate on-site capacity verification; and

– Excavations adjacent to existing structures are possible

The system provides for underpinning existing shallow footings, permitting excavation adjacent to the existing structure to a depth that would otherwise undermine the existing footing. The system allows for excavation to proceed directly adjacent to an existing building without fear of vibration or structural damage to the building.

The system is designed to provide protection to the existing structure by using a combination of foundation support products. Helical extendable round shaft piles are used to underpin the foundation of the existing structure. The structural load from the shallow footing is transferred down to a suitable bearing stratum below the depth of the intended excavation. The soil screw retention wall system, combined with a reinforced shotcrete retaining wall is then used to maintain stability of the cut slope and the underpinning system as the excavation proceeds.

The soil screw retention wall system offer the following benefits:

– Low installed cost

– No vibration

– Shorter installation length

– Ease of installation in limited access areas

– Minimum disturbance to site

– Immediate loading

– On-site load testing capacity

– Reusable in temporary stabilization applications

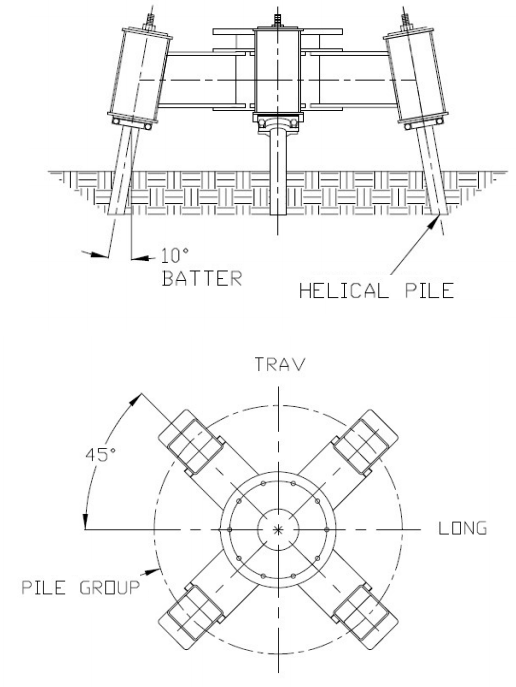

Instant lighting foundations

The instant lighting foundation is used to provide resistance to lateral loads and moments due to wind and other load conditions. The versatility and ease of construction of the system permits great flexibility in a number of applications. Typical uses for these products are foundations for equipment pads, foundation supports for signs, supports for light standards and decorative poles, and other eccentric load applications.

The variability of soil conditions that may exist at a project site, plus the varied nature of loading on structures and how these loads are transferred through foundation elements, requires the use of appropriate Factor of Safety (FS) in design. Generally this factor of safety is a minimum of 2:1 on all permanent loading conditions and a minimum of 1.5:1 for any temporary load situation.

Walkway support bracket system

Helical screw anchors can be used as instant foundation systems for boardwalks. These are typically connected to the walkway using a U-shaped bracket, which sleeves over or into the anchor shaft depending upon the anchor selected. This system has proven most economical in sensitive soils and difficult terrain.

The brackets are used to connect timber or girder beams to helical piles and is also a perfect solution for an environmentally sensitive area which typical construction traffic is prohibited. Minimal disturbance is achieved by using a hand-held torque head, or by a machine that sits on top of the walkway.

Porch and concrete slab support bracket system

The porch pile cap assembly is used to raise the concrete slab edge or non-load bearing wall using a screw lift system. The assembly consists of porch pile cap assembly and helical pile.

The slab support bracket assemblies are used to raise concrete slab using a screw lift system through the slab. This consists of screw lift slab pile assembly and helical pile.

Ultimate mechanical strength = 44kN

Maximum working capacity = 22kN

Maximum lifting capacity = 33kN

Standard access hole: 152mm to 203mm diameter for square shaft piles; 254mm diameter for round shaft piles.

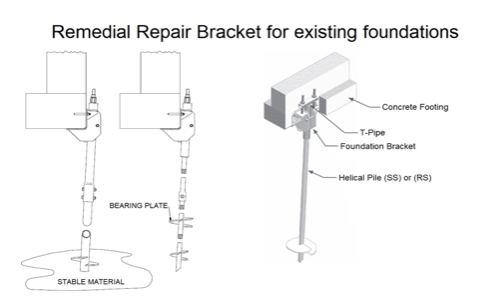

Remedial repair bracket system

Sinking foundations, cracked and buckled walls and uneven floors are problems commonly faced annually by many homeowners. Homes and other structures situated on unstable soils settle when their foundations are subjected to extreme moisture variations or lack proper drainage. A shifting foundation may result in structural damage to the top structure.

The remedial repair bracket system offers a technically superior and cost-effective alternative to other remedial systems to underpin foundations.

The concept is founded on the principle of turning a helical (screw) pile into stable subsoil strata until the torque applied indicates that the necessary load capacity has been achieved. Adjustable brackets are then attached to the base of the foundation walls, connecting the piles to the foundation. The weight of the top structure is then transferred to the piles. In the process, the foundation, walls and floors are repositioned and retained from further movement.

This innovative system contrasts with other more costly and time-consuming methods which require extensive excavation that can disturb site features such as walkways and landscaping.

The load-bearing steel shafts are screwed into the ground independent of the structure and their bearing or holding capacity is verified via torque correlation as the system is installed. The mechanical strength, pile size, product series and maximum working capacity of the repair bracket system are indicated in the table below.

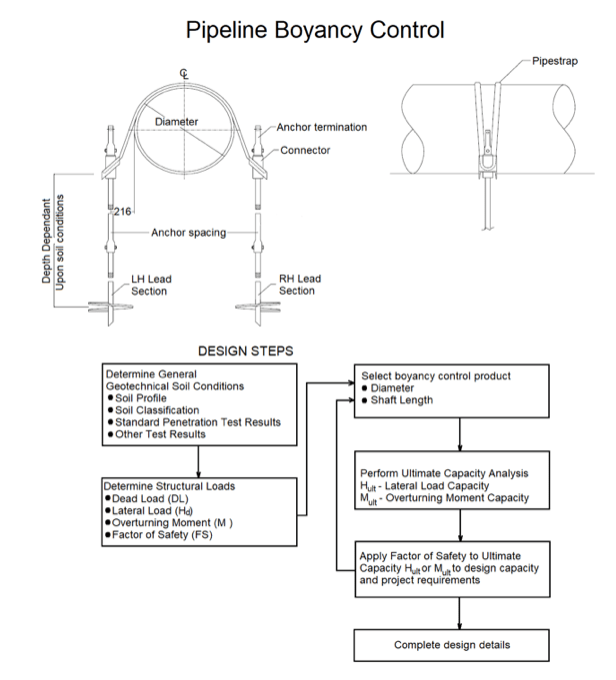

Pipeline buoyancy control

Helical piles can provide an excellent anchor to stabilize all types of pipe lines. Buoyancy of pipelines is a major concern in the design and construction of all pipelines. In soil conditions with a high water table, an empty pipeline with diameter greater than 300mm can be forced to the surface if it has not been anchored. Economics and engineering evaluations show that helical anchors are the predictable, measurable, and economical means for pipeline stabilization.

Custom rapid steel grillage support frames

Our range of foundation solutions help reduce the project duration by up to 70% and simplifies the installation process. Our customized grillage support frames are used to support road signs, gantries, lighting columns, traffic lights, platform and climbing equipment, towers, monopoles, mobile phone masts as well as other city center structures surrounded by underground utilities.

Steel Grillage foundations are used to support towers, gantries, signs, overhead line electrification (OLE) masts and similar structures.